NAVAL DEFENSE

Interconnect systems in Naval Defense

Interconnect systems in the naval defense market face several technical challenges due to the harsh and demanding operating environments encountered in naval operations.

These challenges include:

- Saltwater Exposure: Naval equipment is constantly exposed to saltwater, which can be highly corrosive. Interconnect systems must be designed to resist corrosion and maintain electrical integrity over extended periods.

- Vibration and Shock: Naval vessels operate in rough seas and can be subjected to heavy vibrations and shock from various sources, including gunfire and explosions. Interconnects must be ruggedized to withstand these conditions and ensure reliable connections.

- Harsh Environmental Conditions: Beyond saltwater, naval environments can be exposed to extreme temperatures, humidity, and high levels of UV radiation. Connectors and cables need to be resistant to these conditions to prevent degradation or failure.

- Submersion and Pressure: Some naval systems and equipment may be submerged or exposed to high-pressure conditions. Connectors used in these applications must be hermetically sealed and capable of maintaining their integrity at depth.

naval defense

The technical challenges of interconnect systems

- Compliance with Military Standards: Many defense naval projects require compliance with specific military standards, such as MIL-DTL-38999, which impose stringent requirements on connector performance and durability.

- Electromagnetic Interference (EMI): EMI can be a significant issue in naval vessels due to the presence of various electronic systems and radars. Interconnects need to provide effective EMI shielding to prevent interference with sensitive electronics.

- Size and Weight Constraints: Space can be limited on naval vessels, especially submarines. Interconnect systems need to be compact and lightweight while still meeting the required performance standards.

- High Data Rates: Modern naval vessels rely heavily on data communication for surveillance, communication, and control systems. Interconnects must support high data rates and low latency to ensure effective communication and data transfer.

- Mating and Unmating in Harsh Conditions: In naval operations, connectors must be easy to mate and unmate, even in adverse conditions. Quick-connect and disconnect mechanisms that work reliably in wet, cold, or turbulent environments are essential.

- Safety and Security: Security is a paramount concern in naval operations. Connectors must be designed to prevent tampering, unauthorized access, or interference with critical systems.

Collaboration & custom solutions

Meeting these technical challenges in the defense naval market requires close collaboration between defense contractors, connector manufacturers, and naval engineering teams. It often involves custom solutions tailored to the specific needs of the naval vessel and its mission profiles. Rigorous testing and quality control are also essential to ensure that interconnect systems can withstand the unique demands of naval operations.

NAVAL DEFENSE

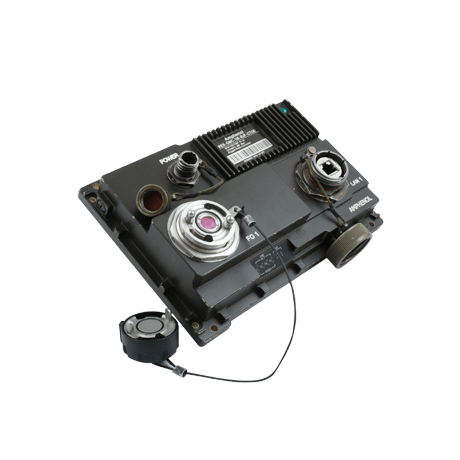

Interconnect solutions for naval defense applications

There are several interconnect solutions that are well-suited for naval applications:

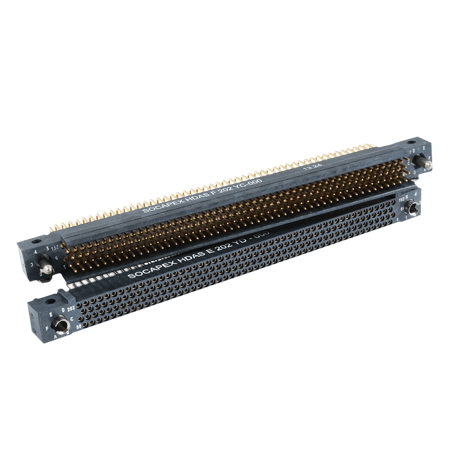

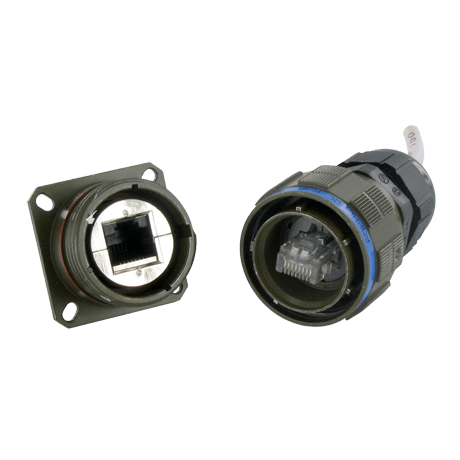

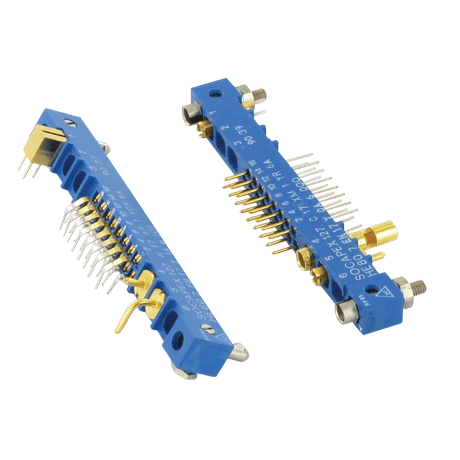

- MIL-STD-38999 series connectors in Marine Bronze: The circular D38999 connectors are designed to meet the demanding requirements of military and aerospace applications and are highly durable and resistant to vibration, shock, and extreme temperatures. They are also designed to be resistant to corrosion (especially in Marine Bronze) and provide secure connections for high-frequency signals.

- Fiber optic connectors: These connectors provide a secure, high-speed connection and are highly resistant to electromagnetic interference (EMI). They are also immune to electromagnetic pulse (EMP) which can be a concern in naval operations.

- Cordsets & cable assemblies: Military harnesses used in naval applications must be able to withstand extreme temperatures, exposure to dust and water, and be able to resist the effects of vibration and shock. Our cordsets & harnesses used in naval communications are also designed to be resistant to electromagnetic interference (EMI).

Reliable interconnect solutions for Naval applications